<script data-ad-client="ca-pub-6864624463949406" async src="https://pagead2.googlesyndication.com/pagead/js/adsbygoogle.js"></script>

Bridge structures are subjected to continuous movements,

undergoing deformations due to various factors like Thermal effects, longitudinal

forces tractive/braking, shrinkage and creep of concrete superstructure, vibration

due to Road/Rail traffic , elastic deformation, wind forces, seismic vibration

etc.

Steel bearings either sliding or roller/rocker are

subjected to corrosion and freezing of parts thus affecting free movement and

require periodical maintenance involving lifting of girder. Further steel

bearings specifically roller bearing, have poor performance under seismic forces. Elastomer as a material

for making bridge bearing capable of dampening seismic vibrations. There is large

scope of further development to enhance its properties and better future performance.

Elastomeric bearing, a type of modern bearing, has number of advantages over steel

bearings like mild steel sliding,

roller cum rocker bearing.

a) These bearings

are inexpensive to manufacture having Longer service life with less maintenance compare to other bearings.

b) Suitable for translation along all axes and for

rotation about any axis.

c) Easy

installation, occupies small space and low height in general.

d) Elastomer has natural

dampening capacity and serves as a shock absorber under moderate range of seismic activity.

e) Acts as an aid to better dispersion of longitudinal

forces to the approaches of Railway bridges.

f) Reinforcing

Steels are enclosed in Elastomer, therefore protected against corrosion.

Further, these bearings have no moving parts to corrode or seize.

g) Under proper quality controlling during manufacture, elastomer

has very high resistance to oils, solvents, ozone and other chemical present in

the environment.

h) Laminated

Elastomeric Bearings may be combined with PTFE/Stainless Steel sliding surface

for larger movement as required.

Movement of Elastomeric Bearing:

Translation: This bearing can deform in long and in trasverse direction. In vertical direction deformation is very small, particularly for laminated bearing widely adopted.

Rotation: This bearing can rotate about all axes by deformation of elastomeric pad.

Rotation: This bearing can rotate about all axes by deformation of elastomeric pad.

Basics of Manufacturing Elastomeric PAD:

When a polymeric

substance is imparted elasticity , it is called Elastomer. A normal rubber is

not useful bearing as it becomes brittle

at low temperature and sticky at high temperature. As such properties of rubber need to be improved to an elastic material by the process of vulcanization, basically by

heating the rubber with Sulphur and other chemicals in a controlled pressure. This transformed polymer has the ability to

behave as an elastic material. It is more flexible, stronger and is able to regain original shape on release after

considerable deformation and even after repeated stretches.

However, behaviour of the bearings in service are strongly dependent on various factors iike compounding, processing and

vulcanization of rubbers. Carbon black is the filler typically used

in making elastomeric bearings to modify the hardness and adjust the stiffness

of the rubber. Once the rubber is vulcanized, its

fluidity is lost even after heating, therefore before vulcanization and cross

linking, it should be moulded into the

desired shape and size and then to Vulcanize.

Natural rubber is poly-

isoprene. It has excellent properties to be an element of many engineering

applications, but it is highly reactive with ozone thus leading to brittle surface

and subsequent cracks. To recover this drawback many synthetic rubbers are

developed, most popular one is Poly-chloroprene which shall be used for

Elastomeric bearing. Throughout the world the most common elastomers used in

bearings are compounds of Natural Rubber (NR) or poly-chloroprene (CR). Both materials can make

very good bearings if they are compounded to have a hardness in the vicinity of

50 to 60. CR would appear to be more desirable

than NR for bridges exposed to extreme chemical environments because of its

better resistance to ozone, oils, acids, and chemical attack. NR bearings creep

less, suffers less low temperature stiffening effect. Choice may be given based on

environmental location of the bridge.

Demerits of Elastomeric bearing:

a) Defects may

arise from poor product quality such as corroded steel, inadequate

vulcanization, lack of proper bond between laminate and elastomer, poor rubber

quality leading to splitting, slippage, bulging and cracking of the rubber,

tearing of cover etc. High degree quality controlling is required to

minimize these effects.

b) Elastomeric

bearings have a tendency to slip if normal pressure is 2 N/mm2 or below and can

“walk” out of place with time if not positively held in place.

c) Although Elastomeric

bearing has adequate resistance to environmental effect , it has adverse effect

during long term service due to weathering and aging and subject to ozone cracking, NR bearing

is more susceptible in this respect.

d) Laminated

Elastomeric Bearings may exhibit varying vertical deflection among the

different bearings in the same bridge.

e) Elastomeric

bearing should not be used as fixed bearing.

f) As a result of

temperature changes, properties of the rubber changes. Elastomer stiffens at

low temperatures increasing shear modulus leading to transmitting more forces

to the substructures while permitting longitudinal movement of the bridge

girder.

g) Translation is restricted to nearly 0.5-0.6

times the thickness of the Pad. For larger movement thicker pad may be provided

taking into account the instability of the bearing.

h) Large rotation may cause enormous hydrostatic pressure

towards the inner edge and offloading /tension on the opposite end.

i) Delamination from steel reinforcement as a result of

shearing stresses near the edge of the bearing.

DETERIORATION AND SERVICE LIFE OF THE ELASTOMER:

Bridge bearings are generally designed to serve for the

required life of the bridge. In the intervening period, replacement of the

bearing may be required but not desirable. It is generally accepted that elastomeric bearings offer a longer service life with less

maintenance compare to many other types of bearings. Although elastomeric bearing has

adequate resistance to environmental elements, however, there is still influence of the environment and aging on the material.

1. Ozone cracking is one concern that is raised with

respect to rubber materials. It reacts with polymer to make it brittle. Effect

on CR is small and generally not

considered a problem. NR is more susceptible to it, but it can be readily

controlled or eliminated by appropriate addition of specified dose of an

anti-ozonant during the compounding process.

2. It is believed that the properties of the bearing

material may change with time because of chemical changes induced by effects of

temperature and elements of weather thus increasing the hardness and shear

modulus of the elastomer and may also reduce elongation at break. Therefore, Resistance to oil and chemical attack is also a possible

consideration in the design of elastomeric bearings depending on the location of its use. CR bearing has a

higher resistance to oil, acids and chemicals compare to NR.

3. Holes in the bearing and reinforcement are subjected to stress

concentration and fatigue failure.

Properties

of Elastomeric materials:

Elastomer is a complex polymer that has a wide variation

in the behaviour depending on chemical composition used in the compounding and

manufacturing process. The most important properties of elastomer are its

hardness, elongation at break, ozone resistance etc. The stress strain

relationship of the elastomer is non linear,

time dependent and temperature depended , does not obey Hooks law. The elastic behavior of rubber

differs fundamentally from that of metals.

The elastic modulus of metals is

very high thus require large force even for a small deformation. The metal

shows a yield point beyond which the deformation increases rapidly with respect

to increase in stress. From this point onwards, the deformation is irreversible

or plastic for metals.

With elastomer, on the other hand, the

stress-strain curve does not show any yield point, however will almost return to their original shape and form unless

they are extended to the point of fracture. Since the forces required

are much smaller against deformation, the

elastic modulus of rubber is very low.

Poisson's ratio (lateral strain divided

by axial strain) applies to both metals

and rubber. Poisson's ratio of elastomer is 0.5. The Poisson's ratio of metals is normally between 1/ 4 and 1/ 3.

The elastomer may have axial tensile strain of few

hundred percent. Slope of stress-strain curve and break point

may also vary considerably depending

on strain rate, temperature and its compounding. From the stress strain

curve published in some research report shown in the sketch, it may be seen that rubber is linear elastic at very small strains, there is distinct

stiffening effect at large strain with steep slope i.e material becomes

stronger & tougher at large strain and

The elastomer may have axial tensile strain of few

hundred percent. Slope of stress-strain curve and break point

may also vary considerably depending

on strain rate, temperature and its compounding. From the stress strain

curve published in some research report shown in the sketch, it may be seen that rubber is linear elastic at very small strains, there is distinct

stiffening effect at large strain with steep slope i.e material becomes

stronger & tougher at large strain andat moderate strains elastomers are apparently softer. Elastomers are very flexible in shear while very stiff in bulk compression (i.e. large bulk modulus). At low temperatures elastomers stiffen leading to significant increase in E value ( modulus of elasticity) and increase in shear resistance i.e. G value (modulus of Shear), an increase in hardness, and a reduction in the elongation at break. The shear stiffness of the bearing is a most important property since higher the stiffness greater will be the forces transmitted to the substructure. However increase in shear resistance can be controlled by selection of an elasotmer compound which is appropriate for the specific climatic conditions. The modes of failure of rubber in elastomeric bearings are not well understood, but it is generally believed that the development of tensile stress in the rubber is the predominant one. Their hardness nearly always lies in the range of 50-60. Laminated bearings with nominal hardness of greater than 60 are prohibited because they generally have a smaller elongation at break, greater stiffness, shorter fatigue life, and greater creep than their softer counterparts. Steel reinforcement is typically much stronger than fiberglass fabric and thus steel reinforced bearings usually have a much higher ultimate load capacity. Shear modulus is the most important mechanical property for design and it should be given preference over hardness to specify the material.

Types of Elastomeric

Bearing mostly used as bridge bearing:

a) Plain Elastomeric

Pad- This type of bearing consists of a solid block of elastomer without

reinforcing plates, suitable for small vertical load may be up to 40 MT. Due to

its relatively low compressive strength

the plain elastomeric pad may be used under shorter prestressed concrete Box

Girder.

b) Laminated elastomeric pad- These are reinforced with laminates of steel plates widely used as

bridge bearing. When vertical load is imposed on the bearing, the steel plates partially restrain the elastomer from

bulging and consequently shear stress is

developed at the interface of the rubber

and the reinforcement. This cause

tensile stresses in the reinforcement. Thickness and

number of steel plates depend on the magnitude of the vertical load which the bearing has to support. The steel plates are chemically bonded to the rubber in

layers during vulcanization. Steel laminate permits to support relatively higher compressive load and larger displacement than plain elastomer pad. Horizontal

movement is permitted due to shearing deformation of the total thickness of the

elastomer layers in any direction. Rotational displacement is accommodated by variation of compressive strain of elastomer about any axis. (as shown in the sketch below)

b) Laminated elastomeric pad- These are reinforced with laminates of steel plates widely used as

bridge bearing. When vertical load is imposed on the bearing, the steel plates partially restrain the elastomer from

bulging and consequently shear stress is

developed at the interface of the rubber

and the reinforcement. This cause

tensile stresses in the reinforcement. Thickness and

number of steel plates depend on the magnitude of the vertical load which the bearing has to support. The steel plates are chemically bonded to the rubber in

layers during vulcanization. Steel laminate permits to support relatively higher compressive load and larger displacement than plain elastomer pad. Horizontal

movement is permitted due to shearing deformation of the total thickness of the

elastomer layers in any direction. Rotational displacement is accommodated by variation of compressive strain of elastomer about any axis. (as shown in the sketch below)

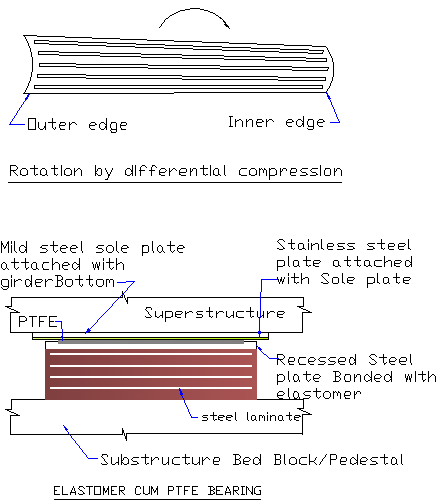

Shearing deformation is unaffected by the presence of reinforcement. When large horizontal movement has to be accommodated, a poly tetra fluoro ethylene (PTFE) slider is added (shown in fig below). A stainless steel plate slips with very little friction on the sheet of PTFE.

Elastomers are almost incompressible, but deformable under vertical

load. so when a steel-laminated bearing is loaded in compression,

the elastomer expands laterally due to the Poisson effect. That expansion is

partially restrained by the steel plates to which the elastomer layers are

bonded, and the restraint results in bulging of the layers between the plates.

The bulging creates shear stresses at the bonded interface between the

elastomer and steel. If they become large enough they can cause shear failure

of the bond or the elastomer adjacent to it. This is

the most common form of damage in steel-laminated elastomeric bearings, and is

the reason why limitations on the shear strain in the elastomer dominate the

design requirements.

It is necessary to understand the behaviour of

elastomeric pad against imposed load and surface condition. When subjected to vertical load the elastomer deforms

vertically and expands laterally due to the Poisson effect also termed as bulging. A plain elastomeric pad compressed between two friction less

surfaces has deformed as shown in Fig-1A before compression and Fig-1B after compression with a lateral expansion of uniform depth. Under rough contact surfaces, the plain pad has deformed in the shape of bulge as shown in Fig-2A. However in case of laminated pad, the bulging area has reduced considerably as shown in fig-2B due to laminated steel.

It is noted that Plain pad is subject to excessive bulging leading to greater vertical deflection, an indicative of less compressive stiffness. Freedom of bulging is partially restrained by the steel plates to which the elastomer layers are bonded and the restraint results in limited bulging of the elastomer layers between the plates. The bulging creates shear stresses at the bonded interface between the elastomer and steel resulting development of tensile stresses in the reinforcement. If they become large enough they can cause shear failure of the bond or the elastomer adjacent to it. Steel lamination would increase the compressive stiffness of the bearing simultaneously reducing the vertical deflection of the bearing. However, the addition of internal reinforcing layers has no appreciable role on the shear stiffness if the total rubber thickness is unchanged as shown in Fig-3A & Fig-3B. In both cases deformation is δ

Thus, the horizontal and vertical stiffness may be controlled independently within wide limits by a suitable choice of reinforcement.

surfaces has deformed as shown in Fig-1A before compression and Fig-1B after compression with a lateral expansion of uniform depth. Under rough contact surfaces, the plain pad has deformed in the shape of bulge as shown in Fig-2A. However in case of laminated pad, the bulging area has reduced considerably as shown in fig-2B due to laminated steel.

It is noted that Plain pad is subject to excessive bulging leading to greater vertical deflection, an indicative of less compressive stiffness. Freedom of bulging is partially restrained by the steel plates to which the elastomer layers are bonded and the restraint results in limited bulging of the elastomer layers between the plates. The bulging creates shear stresses at the bonded interface between the elastomer and steel resulting development of tensile stresses in the reinforcement. If they become large enough they can cause shear failure of the bond or the elastomer adjacent to it. Steel lamination would increase the compressive stiffness of the bearing simultaneously reducing the vertical deflection of the bearing. However, the addition of internal reinforcing layers has no appreciable role on the shear stiffness if the total rubber thickness is unchanged as shown in Fig-3A & Fig-3B. In both cases deformation is δ

Thus, the horizontal and vertical stiffness may be controlled independently within wide limits by a suitable choice of reinforcement.

The elastomeric bearing permits horizontal translation by

shear strain as shown in Fig-3B.

Functional properties of Elastomeric bearing:

Elastomeric bearing shall generally transmits vertical

load evenly on the substructure and allows small rotation and longitudinal movement. They are

very stiff in resisting volume change but are very flexible when subjected to

shear or pure uniaxial tension. They are generally reinforced with steel plates

in alternate layers to enhance compressive and vertical stiffness and reduction in the outward bulging as well as

vertical deflection within a acceptable range. The longitudinal movement of the

bridge deck due to temperature changes and other effects are accommodated by

the shear deformation of the bearing utilizing the property of flexibility in

shear as shown in fig 3A and below. It may be

ensured that horizontal translation is being provided by elastomeric bearing

without any slippage of the bearing either at interface with superstructure or

with substructure. Therefore, the movements are allowed without any relative

movement of parts at any interface . Rotational deformation of the

girder at the bearing point is due to variation of compressive strain. In case of excessive rotation required due to

larger span or else, inner edge of the bearing is heavily compressed while the

outer edge is subjected to offloading and tensile stress. This has to be

ensured in the design that bearing must not

be under tension at any stage. By allowing

rotation and translation, transmission of large magnitude of horizontal loads

and moments on piers or abutments of the bridge can be largely reduced.

Relation between Shear deformation (δ) and Elastomeric Pad thickness(t):

Relation between Shear deformation (δ) and Elastomeric Pad thickness(t):

Shear force F

Shear stress=

_________ ____ ------------(1)

Plan area axb

δ

Shear strain =

__ -----------(2)

h

δ = deformation

h = Total thickness of elastomer

F = horizontal/Longitudinal force i.e Shear force

a = length of elastomeric pad along the span

b = width of elastomeric pad across the span.

shear stress

Shear Modulus, G = __________

shear strain

Fxh

Shear strain,

δ =________

G(axb)

Thus for a given size of bearing and its property, value

of G, a, b and Shear force, a calculated value, F will not vary, hence the shear deformation δ will be proportional to thickness of elastomeric pad (h).

Therefore, δ ∞ h

Elastomeric combined

with PTFE Sliding Bearing:

PTFE sliding elastomeric bearing, a type of elastomeric bearing pad, is formed by adhering a layer of 1.5

mm to 3 mm thickness PTFE on the recessed steel plate which is bonded with laminated

elastomeric pad during manufacture. A sketch with required details is

shown in Fig below. Translation performed by Laminated elastomeric bearing (without PTFE) is generally limited to nearly 60mm or so.

When very large

horizontal movement is required, a stainless-steel & PTFE slip

plane is added on top of a conventional Elastomeric Bearing with very low

coefficient of friction at the interface thus the girder end can freely slide on the bearing surface with large

movement. The

rotation, therefore, is provided by elastomer due to differential compression

and translation by sliding at the interface of stainless steel and PTFE. Daily movements are

taken within the elastomer, greater movements cause greater shear force in the

elastomer, which overcomes the friction at the PTFE/stainless steel interface thereby accommodating

these additional movements through sliding.

PTFE sliding

elastomeric bearing is suitable for bridges with medium or small loading having

large displacement.

Shape factor of Elastomeric pad:

For long spans, thicker pads are

needed to have adequate shear deformations and accommodate large horizontal

movement. Plain elastomeric pad are subject to excessive bulging due to lack of

enough compressive and vertical stiffness which is measured by shape factor.

Compressive stiffness of the elastomeric pad of same thickness and same plan dimension, can be

enhanced by increasing the shape factor

and thus excessive bulging can be

controlled. Shape factors can be increased by additional layers of laminated steel

plates in the elastomer as per requirement of design. In fact, shape factor

is a measure of the bulging restraint.

Higher the shape factor, higher is the stiffness and lower is the bulging of elastomer

sides.

The shape factor (S), defined as the

ratio of the loaded area(plan area) to the area of the sides free to bulge, The shape factor of a rubber layer is a non-dimensional

parameter which gives a good indication of the compressive stiffness of the

layer. The shape factor of most reinforced bridge bearings may fall in the range of 4 to 12.

For a rectangular

bearing of sides 2a and 2b, shape factor as per definition,

S=(2a*2b) / (2(2a+2b)*t)

or

S= (a*b) / ((a+b)*t) -------------------------------------------------------(1)

for a circular

bearing of diameter D,

S=(π*D²) / (4*π*D*t) or

S=D /( 4*t) -----------------------------------------------------------------(2)

From equation 1 & 2 above, shape factor increases when t, the thickness of elastomer reduces which can be done by introducing more layers of steel reinforcement plates of

small thickness say 1-3mm as per design calculation. A sketch is shown in Fig-6.

Anti slip Devices in Elastomeric Bearing:

Elastomeric bearings have a tendency to slip if the

minimum normal pressure is less than 2 MPa (2 N/mm2). Such a situation is

likely to occur when elastomeric bearings are used in steel plate girders

having spans ranging from 12.2 m to 30.5 m with reduced weight and to undergo

large longitudinal movements. All such bearings, therefore, require some

anti-creep or anti-slip device. Sketch

is shown in Fig below

0 Comments