WATER CONTENT VS DRY DENSITY RELATIONSHIP

IS 2720, Part-VII deals with the method of Test for determination of water content - Dry density relationship using light compaction.

The purpose of this laboratory test is

1. To find out the Optimum Moisture Content(OMC) at which Maximum Dry Density (MDD) is obtained.This relationship varies according to changes in the soil characteristics.

2. To achieve the maximum compaction while compacting by site equipment, using the OMC obtained from the laboratory.

3. To assess the degree of compaction / dry density achieved, time to time, for comparing with the 'Maximum Dry Density' obtained in the Laboratory, so that very good controlling will be generated automatically among the site official to achieve dry density of site soil nearer to the MDD.

4. With knowledge of water content-dry density relationship better control of the field compaction of soil fill is possible.

A- Suitability of Test:

This method of test is suitable for cohesive soil but does not suit so well to the compaction characteristics of sand, gravel etc where grains are displaced during ramming.

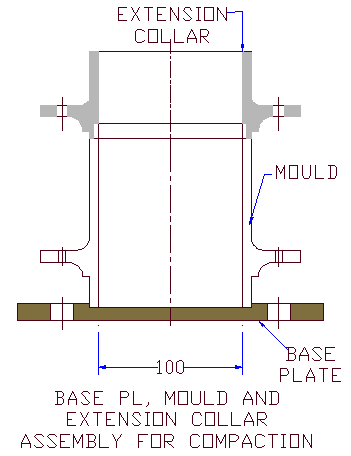

B- APPARATUS

|

| Fig-1 |

|

| Fig-2 |

8. Mixing Tools- Miscellaneous tools, such as tray or pan, spoon. trowel and spatula. or a suitable mechanical device for thoroughly mixing the sample of soil with additions of water.

9. Metal Rammer- It shall conform to IS : 9198-1979.

C- SOIL SPECIMEN- Air dried soil sample about 6 kg passing 19-mm IS sieve ( for soils

not susceptible to crushing during compaction), or about 15 kg of

material passing a 19-mm IS sieve (for soil susceptible to crushing

during compaction).

In this test a 2·6 kg rammer falling through

a height of 310 mm is used.

D- PROCEDURE- Soil not Susceptible to Crushing during compaction-

1. A 5-kg air dried soil passing the 19 mm IS test sieve shall be taken. For soils containing larger proportions of gravel, the use of a bigger mould ( 2250 cc) will avoid errors.

2. The sample shall be mixed thoroughly with

a suitable amount of water The amount of water to be mixed at the commencement of the test depends upon the type of soil under test. In general, with sandy and gravelly soil. a moisture content of 4 percent to 6 percent would be suitable, while with cohesive soil a moisture content about 8 percent to 10 percent below the plastic limit. If plastic limit is 15(say), moisture to be added 15-9(Av)=6%.

3. It is important that the water is mixed thoroughly and adequately

with the soil, since inadequate mixing gives variable test results. This

is particularly important with cohesive soils when adding a substantial quantity of

water to the air dried soil. With clays of high plasticity, or where hand mixing is

employed, it may be difficult to distribute the water uniformly through the air

dried soil by mixing, and it may be necessary to store the mixed sample in a sealed container for a minimum period of about 16 hours before continuing with the

test.

5. The compacted soil specimen shall be removed from the mould and placed on the mixing tray. The water content of a representative sample of the specimen shall be determined as in IS: 2720 (Part II )- 1973

The remainder of the soil specimen shall be broken up, rubbed and passed through the 20-mm IS test sieve, and then mixed with the remainder of the original sample. Suitable increment of water shall be added successively and mixed into the sample. In general, increments of 1 percent to 2 percent are suitable for sandy and gravelly soils and 2 percent to 4 percent for cohesive soils. To get the better accuracy of the test it is often advisable to reduce the increments of water in the region of the optimum moisture content. The above procedure from para D(4 ) to D(5) shall be repeated for each increment of water added. The total number of determinations made shall be at least five to get a suitable curve. The range of moisture content should be such that the optimum moisture content, at which the maximum dry density occurs, must be within that range.

E- Procedure- Soil susceptible to crushing during compaction:

1. The soil should be considered susceptible to crushing durlng compaction if the sample contains granular material, containing soft limestone, sandstone, etc. which is reduced in size by the action of the 2.6 kg rammer. The procedure given in para 5.2 of IS 2720 for soils susceptible to crushing during compaction can be applied to all soils if it is convenient to do so as per Note-1 given in IS 2720, para 4.1

2. The procedure as per para 5.2 of IS 2720 amalgamating the notes-

Five or more numbers of 2.5 kg sample of air dried soil passing the 20-mm IS test sieve, shall be taken. However, for the soils containing larger proportions of gravel, the use of a bigger mould 2250 ml, avoiding major errors, shall be used. The samples shall each be mixed thoroughly with different amounts of water to give a suitable range of moisture contents .At the commencement a moisture content of 4 percent to 6 percent would be suitable for sandy or gravelly soil, while with cohesive soil a moisture content about 8 percent to 10 percent below the plastic limit. i.e if plastic limit is 15, moisture to be added 15-9(average)=6%. The range of moisture content shall be such that , the maximum dry density occurs within that range.

a) Each sample shall be treated as in Para D(4) above.

b) Each compacted specimen shall be treated as in Para D(5).

c) The remainder of each soil specimen shall be discarded.

F- Compaction in large size mould

For compacting soil containing coarse material up to 40 mm size, the 2250 CC mould should be used, A sample weighing about 6 kg and passing, the 4O-mm IS sieve is used for the test. Soil is compacted in three layers, each layer being given 55 blows of the 2·6.kg rammer. The rest of the procedure is the same as para D & E above above.

G- CALCULATION

Bulk Density – γm in g/cc, of each compacted specimen shall be calculated from the equation: γ m = (m2 –m 1) / Vm,

m1 = weight of mould + Base Plate, as in para D(4) at the start.

m2 = weight of mould +

Base Plate + compacted soil as in D(4) last line

Vm= Volume of the mould in cm3

w = moisture content, if the value is 15%, then w=15

All values are known, γ m can

be determined from the formula above.

Dry density, γ d = 100 γ m / (100+w) in gm/cm3 at moisture content w. This way γd & w can be determined for all specimen and a graph can be drawn.

A typical Graph Showing Moisture content(%) and Dry Density (Kg/m3) in the fig-5

0 Comments